Prepainted Steel Coil Corrugated Metal Roofing Sheet Forming Machine (XM3-52)

Basic Info

Model No.: XM3-52

Product Description

Model NO.: XM3-52 Forging Forming Method: Mold Forging Feature: Automation Warranty: 12 Months Advantage: Easy to Maintenance Width: 600-1250mm General Width: 760, 800, 914, 1000, 1200, 1219, 1250 Technique: Hot Rolled Power(W): 4 Kw Voltage: 380V/50Hz Trademark: X&M Origin: Anping, China Type: Hydraulic Machine Power Source: Hydraulic Pressure Certification: ISO9001 Customized: Customized Condition: New Thickness: 0.14 --1.5 Mm Painting: Top 17-28micron, Back 5-9micron Dimension(L*W*H): 6500mm*1400mm*1500mm Weight: 4 Tons Production Speed: 8-12 Meters Per Min Specification: 6050x1685x2100mm HS Code: 84629910 Corrugated Sheet for Roofing & Wall Cladding

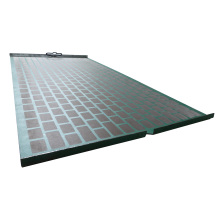

Corrugated sheet is a new option for roofing and wall cladding construction.

It is tough, durable in color and lightweight, better than metal and galvanized sheet. What's more, it will never rust in heavy industry park.

Why Corrugated

Corrugated sheet is often used in the building industry as a low-maintenance material, particularly in Ireland, United Kingdom, and United States where it is known as vinyl, or vinyl siding.

Features

Corrugated roof sheet is made of prepainted galvanized steel, resistant to acids, fungi and humidity with prominent quality. It remains stable in physical performance of -40° C to 80° C.

The corrugated design not only provides an unique appearance, the sheet itself is also waterproofing, boosting drainage in rainy and snowy area as well.

The anti-corrosion performance of corrugated roof tile is suitable for most applications in coastal areas with severe salt fog corrosion, and the areas with severe air pollution, especially in heavy industrial park.

Application

Corrugated sheet is best installed on industrial building, agricultural building, factory, warehouse, mobile home, manufactured home construction, steel structure, shopping mall.

Contact us if you need more details on Roofing Sheet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Forming Machine、Metal Roofing Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Corrugated sheet is a new option for roofing and wall cladding construction.

It is tough, durable in color and lightweight, better than metal and galvanized sheet. What's more, it will never rust in heavy industry park.

Why Corrugated

Corrugated sheet is often used in the building industry as a low-maintenance material, particularly in Ireland, United Kingdom, and United States where it is known as vinyl, or vinyl siding.

Features

Corrugated roof sheet is made of prepainted galvanized steel, resistant to acids, fungi and humidity with prominent quality. It remains stable in physical performance of -40° C to 80° C.

The corrugated design not only provides an unique appearance, the sheet itself is also waterproofing, boosting drainage in rainy and snowy area as well.

The anti-corrosion performance of corrugated roof tile is suitable for most applications in coastal areas with severe salt fog corrosion, and the areas with severe air pollution, especially in heavy industrial park.

Application

Corrugated sheet is best installed on industrial building, agricultural building, factory, warehouse, mobile home, manufactured home construction, steel structure, shopping mall.

| Configurations | Manual Uncoiler ,Guiding Platform ,Coil Strip Leveler ,Main Machine Of Roll Forming ,Electro-Motor,Cutting Device ,Hydraulic Station ,PLC Control, Supporter Table. |

| Control System | PLC Delta Inverter |

| Main Frame | 300mm H-Beam |

| Main Power | 3 kw |

| Pump Power | 3 kw |

| Power Supply | 380V, 3-Phase,50Hz |

| Forming Speed | 8-12m/min |

| Roll Station | 11 stands |

| Roller Diameter | 72mm |

| Hydraulic Pressure | 10-12MPa |

| Forming Size | 1000mm |

| Feeding Thickness | 0.3-0.8mm |

| Feeding Width | 1250mm |

| Backboard Thickness | 14mm |

| Chain Size | 20mm |

| Cutter Standard | Cr12 |

| Roller Standard | Cr12 |

| Cr-Plating Size | 0.05mm |

| Overall Size | 6500 × 1400 × 1500mm |

| Total Weight | 2.8T |

Product Categories : Wire Mesh Machine

Premium Related Products

Other Products

Hot Products

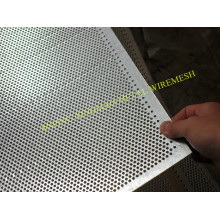

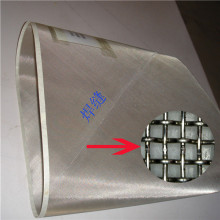

Common Nails (Factory)SS 302 304 316L 430 punched/perforated metal sheetNails Machine (good quality)wire Inserting wire producing machineExpanded metal mesh machinestainless steel filterfibreglass window wire mesh screensteel lattice plateGlavanized Expanded Lattice steel plategarden fence nettinggood razor barbed wire machinehigh-quality chain link fencegalvanized grassland fencegood quality,hot dipped galvanized hexagonal wire meshgalvanized crimped wire meshpvc coated wire